Adding specialized coatings to ice protection systems can significantly improve the efficiency and performance of those systems. The Dynamic Ice Accumulation Test (DAT) is used to:

- Evaluate the performance of different ice protection systems (electrothermal, fluid based, electromechanical, etc.) in an Icing Wind Tunnel under representative atmospheric conditions.

- Evaluate the benefit of adding a coating to these ice protection systems to create a hybrid system.

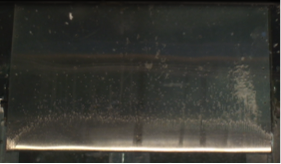

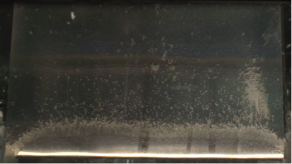

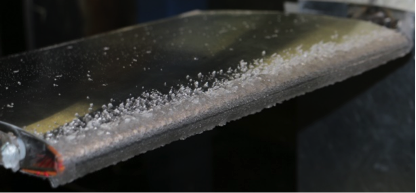

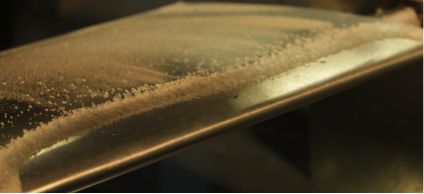

There are multiple ways in which coatings can improve ice protection systems, such as reducing power consumption, eliminating runback water with superhydrophobic properties, or reducing ice adhesion to the surface. By controlling the Liquid Water Content (LWC), Median Volumetric Diameter (MVD), temperature, and speed of the AMIL Icing Wind Tunnel, an icing cloud, representative of real atmospheric conditions, is produced to create any type of dynamic ice accumulation, such as rime and mark ice, in the test section of the tunnel.

The ice protection system, integrated with an aerodynamic profile or another structure, is submitted to the icing cloud in the wind tunnel test section for a fixed period of time. During the icing event, the lift, drag and pitching moments can be monitored to evaluate the lift lost and increase in drag with an aerodynamic balance. The test parameters are also recorded during the test run.

After evaluating the efficiency of the ice protection system, the profile is coated with candidate coatings and tests are repeated under the same conditions for the same period of time. The results are compared and the effect of each coating on the system’s performances are quantified. This test is a representative, quick and inexpensive way to evaluate an ice protection system and assess how a hybrid solution with a specialized coating can further improve its efficiency.